Save Cost, High Output.

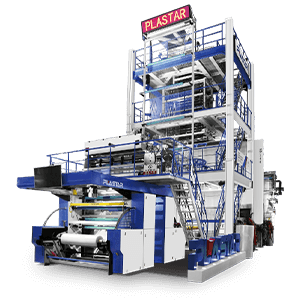

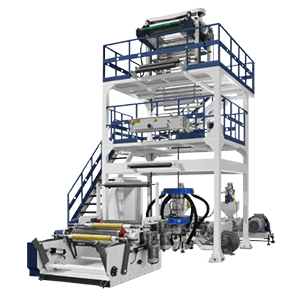

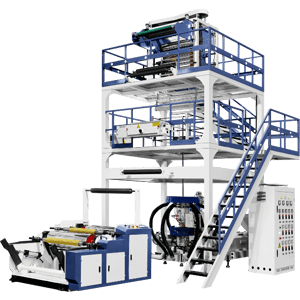

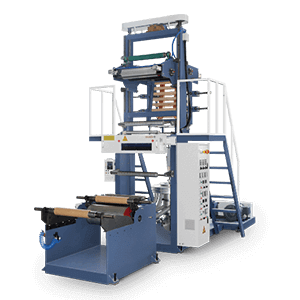

ABA Three-layer Co-extrusion Blow Film Machine

Aoxiang Packaging Machinery production of ABA three-layer co-extrusion blown film machine has a unique advantage in the production of HDPE, LDPE and LLDPE materials.Through the multi-layer co-extrusion, the physical strength of the film is improved. The two main motors supply three-layer extrusion. One provides internal and external coating, while the other provides internal filled layer. It can reach the purpose of host configuration reduction, cost reduction, energy conservation and low consumption.

Meanwhile, the internal filling layer can be added recycled material and calcium carbonate, whose proportion is more than 80% of total. The raw material cost in the process of production can be greatly reduced to provide clients with a strong market competitiveness.

| Model | SD-2LABA800 | SD-2LABA1000 | SD-2LABA1200 | SD-2LABA1500 |

|---|---|---|---|---|

| Suitable Material | HDPE/LDPE | |||

| Film Width | 800 mm ( folding width ) | 1000 mm | 1200 mm | 1500 mm |

| Film Thickness | 0.008 - 0.1 mm | |||

| Max. Output | 100kg / h | 120kg / h | 120kg / h | 200kg / h |

| Extruder | ||||

| Screw Diameter | 55mm; 55mm | 55mm; 55mm | 55mm; 65mm | 55mm; 75mm |

| Screw L/D | 30:1 | |||

| Barrel Cooling | Water Cooling | |||

| Main Motor Power | 22kw; 22kw | 30kw; 30kw | 22kw; 37kw | 22kw; 45kw |

| Total Power | 70kw | 100kw | 100kw | 105kw |

| Die Head | ||||

| Die Head Type | Three layers ABA die head | |||

| Air Ring | Double lips air ring | |||

| Traction Roller Width | 1000 mm | 1200 mm | 1400 mm | 1700 mm |

| Effective Width | 800 mm | 1000 mm | 1200 mm | 1500 mm |

| Traction Speed | 120m / min | |||

| Winding Unit | ||||

| Wingding Type | Friction type automatic single / double winder | |||

| Wingding Speed | 120m / min | |||

| Voltage | 380V, 50Hz | |||

| Dimension | 5000 * 3000 * 6500 mm | 6000 * 4000 * 7000 mm | 6000 * 4000 * 6500 mm | 6000 * 4000 * 8500 mm |

| Weight | 4.5 T | 5 T | 5 T | 5.5 T |

200kg拌料机

四组份喂料机

失重式喂料机

电晕处理架

边料回收机

边料回收机-带上料

冷水B

空压机

吸料机