Kicking Off the Year with Red Envelopes!

With the spring breeze upon us, we're delighted to announce that our company has officially restarted operations!

As a token of appreciation for the relentless hard work and dedication of our team members, we've prepared special red envelopes to kick off the year.

Enhance competitiveness from production

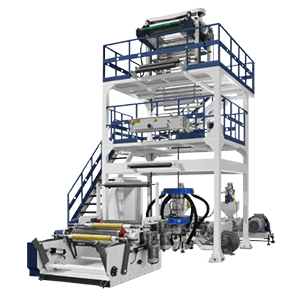

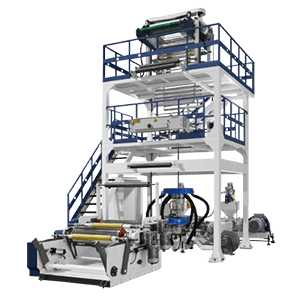

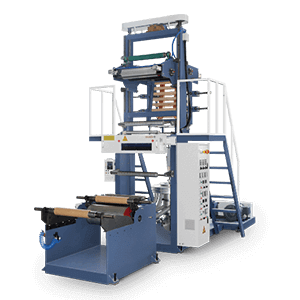

Machine with two sets of extrusion parts and a three-layer co-extrusion die head, wherein the surface layers share an extruder, which we call A layer, the other extruder is for the middle layer, we call it B layer, so the blown out film structure is A, B, A three-layer co-extruded film.

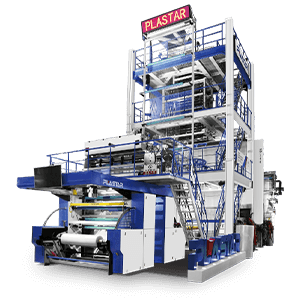

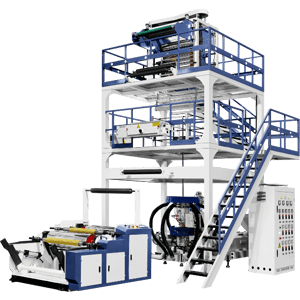

Three Structures of Film Blowing Machine

Film blowing machine products suit for high-grade packaging film, which is with good barrier properties, preservation, moisture, frost, oxygen barrier, oil barrier, can be used in light and heavy packaging process, such as fresh fruit, meat, pickles, fresh milk, liquid drinks, medical & other Packages.

Illustration: the advantages of multi-layer co-extruded

In order to meet the customer’s special requirement on production process, co-extrude multi-functional plastic film with various materials (such as breathable, waterproof, insulation, toughness, etc.) and after years of research and practice development, our company Develop multi-layer co-extruded blown film machine.