In order to meet the customer’s special requirement on production process, co-extrude multi-functional plastic film with various materials (such as breathable, waterproof, insulation, toughness, etc.) and after years of research and practice development, our company Develop multi-layer co-extruded blown film machine. Its purpose is to play the advantages of a variety of materials and avoid some of the shortcomings of a single material or mono-layer blown film machines. Aoxiang’s principle is to provide customers with market competitiveness film blowing machine.

In multiple layers, such as PP, PE co-extrusion film blowing machine, it uses the good advantage of combination of two characteristics of high hardness characteristics of PP material and brightness features of PE material, to produce a film. Multi-layer co-extruded blown film machine can be divided into few types, such as two-layers co-extruded blown film machine, three-layers co-extruded blown film machine, five-layers co-extruded blown film machine,seven-layers co-extruded blown film machine and others.

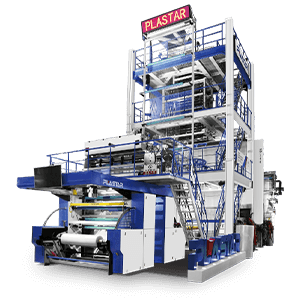

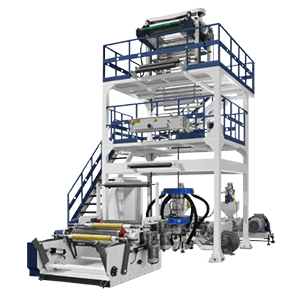

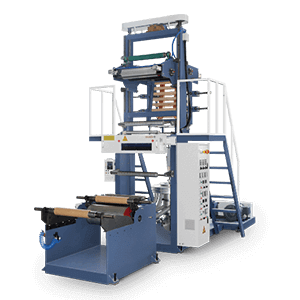

Three layers co-extrusion blown film production line adopts the new type of high efficiency and low energy consumption extrusion line with the IBC film cooling system inside the bubble, + 360 degree for traction on the horizontal rotating system and photoelectric automatic correction device, fully-automatic winding and film tension control, advanced technology such as computer screen automatic control system. Compared with the similar equipment, it has the advantages of higher output, better plasticizing and lower consumption as well we easier operation, completely solving winding size issue, and makes the product quality up to a new step. The characters of our film are with high transparency, durability, high toughness and the best low temperature hot cutting and composite fastness as well as crimp resistant. As its good barrier property, keeping fresh, well protected against dampness, frost proof, oxygen insulation, oil resistant, the film can be widely used for light and heavy packaging, such as all kinds of fresh fruit, meat, pickles, fresh milk, liquid beverage, medical supplies and etc.

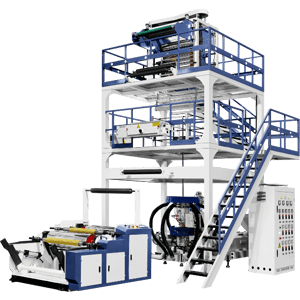

Five co-extruded blown film unit, mainly for HDPE, LDPE, LLDPE, EVA and other gas barrier function material, is generally used for heavy-packaging, high-grade food bags, vacuum bags, liquid packaging bags and other packaging film , to reach preservation, airtight, to extend shelf life packaged purpose Aoxiang can not develop without your requirements, customers’ satisfaction is the greatest hornor of Aoxiang.