Company News

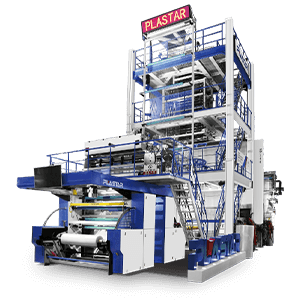

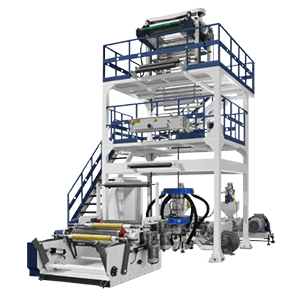

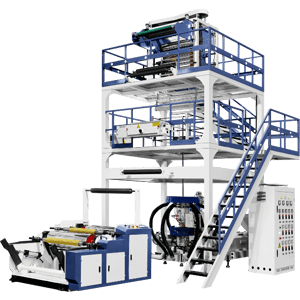

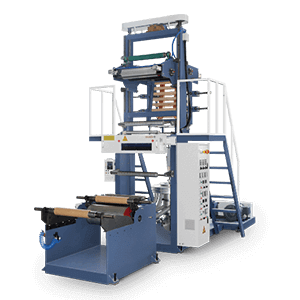

Three Structures of Film Blowing Machine

Film blowing machine products suit for high-grade packaging film, which is with good barrier properties, preservation, moisture, frost, oxygen barrier, oil barrier, can be used in light and heavy packaging process, such as fresh fruit, meat, pickles, fresh milk, liquid drinks, medical & other Packages.

Film blowing machine production theory:

Blowing machine is a plastic machinery, main working principle: put the dried polyethylene material to the hopper, by weight of the material and it falls from the hopper into the screw, oblique facet when the pellets in contact with the threaded oblique edges, rotating plastic generating thrust perpendicular to the plane oblique ridge, the plastic particles onward, the process goes on, because the friction and particle collision friction plastic screw, plastic and barrel time between, but also due to the external heating barrel gradually dissolves. Molten plastic through screw & screen changer to filter impurities, Extruded out from the die head, cooled by the air ring and blown film through the word board, pulling rolls, winder, then the film rolls are finished.

Description of three structures of film Blowing machine :

1. Extruder: Consists of screw, barrel, hopper, gear box and drive motor. And drive motor can be electromagnetic speed motor or Frequency General Motor. Through the motor belt, motor drives gear box and makes the screw do rotation jobs inside of the barrel; Then plastic materials melt with external heating and come out from die head gap.

2. The cooling unit: consists of air ring, pipe, air blower and other components.

3. The electrical control unit: generally production line with operation of the unit is equipped with a cabinet by the general pressing through the main power button, turning on the total motor switch, separating buttons control the heaters of screw, three-way, die head. We use temperature thermocouple on the key parts of heating ring with automatic temperature control function, during the normal production process. Furthermore, the temperature can be automatically controlled to ensure that the production process is stable and reliable.

Film blowing machine production theory:

Blowing machine is a plastic machinery, main working principle: put the dried polyethylene material to the hopper, by weight of the material and it falls from the hopper into the screw, oblique facet when the pellets in contact with the threaded oblique edges, rotating plastic generating thrust perpendicular to the plane oblique ridge, the plastic particles onward, the process goes on, because the friction and particle collision friction plastic screw, plastic and barrel time between, but also due to the external heating barrel gradually dissolves. Molten plastic through screw & screen changer to filter impurities, Extruded out from the die head, cooled by the air ring and blown film through the word board, pulling rolls, winder, then the film rolls are finished.

Description of three structures of film Blowing machine :

1. Extruder: Consists of screw, barrel, hopper, gear box and drive motor. And drive motor can be electromagnetic speed motor or Frequency General Motor. Through the motor belt, motor drives gear box and makes the screw do rotation jobs inside of the barrel; Then plastic materials melt with external heating and come out from die head gap.

2. The cooling unit: consists of air ring, pipe, air blower and other components.

3. The electrical control unit: generally production line with operation of the unit is equipped with a cabinet by the general pressing through the main power button, turning on the total motor switch, separating buttons control the heaters of screw, three-way, die head. We use temperature thermocouple on the key parts of heating ring with automatic temperature control function, during the normal production process. Furthermore, the temperature can be automatically controlled to ensure that the production process is stable and reliable.